Cost-Effective Low-Voltage DC Barrier Gates: Efficient Access

Control Easy Installation & Maintenance

As a solution for vehicle access management, BRDC-110 DC road gates

are widely used in parking lots, neighborhoods, industrial parks

and other places. Its stability, reliability and automation

features make it an important part of modern traffic management

systems.BRDC-110 DC road gates can realize automated management through a

variety of control methods:Remote control: switch control through remote control, convenient

for remote operation.

Auto-sensing: Automatically open the gate after detecting the

vehicle through sensors (such as infrared, ground sensors, etc.).

License plate recognition: Automatically open the gate by

recognizing the license plate information of vehicles.

Control Board Wiring Diagram

- Note: it is best to use BVR wire, do not use network wire

Left And Right Split Wiring Diagram Of Barrier

Left and right split wiring diagram of the barrierConnection Method Of Common Cathode And Common Anode Of Traffic Light

Figure 2 The wiring diagram of common cathode and common anode of traffic lightProduct Performance Characteristics- The movement adopts side mounting type, easy installation and

compact structure.

- The main body of the movement is made of aluminum alloy,

manufactured by die-casting process, with reliable mechanical strength, beautiful appearance, precise size and good

heat dissipation.

The movement adopts gear reduction transmission, high transmission

efficiency, small loss of power output; gear material SCM421, carburizing heat treatment process, precision

grinding processing, anti-wear, impact resistance, service life far

exceeds the worm gear transmission structure.

The movement adopts DC brushless motor, with large output torque

and small size, and the speed can be adjusted arbitrarily through the controller, and the deceleration buffer can

be realized when dropping and lifting the pole into place, so that

the gate pole can be put into place smoothly.

The motor adopts DC24V safety voltage, which avoids the electric

shock accident caused by leakage, and provides more protection for personal safety.

Internal Dimensions

Movement Outline Picture

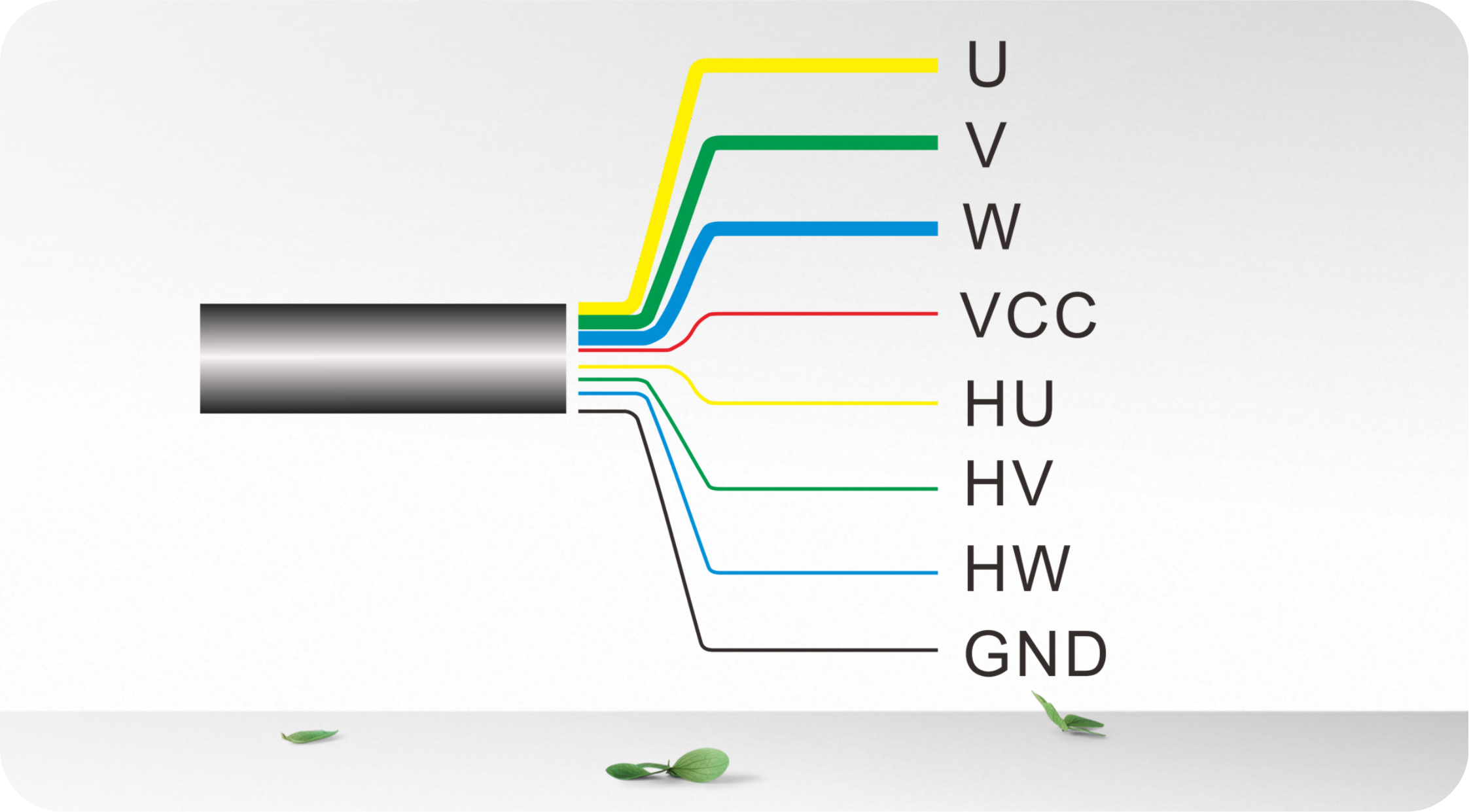

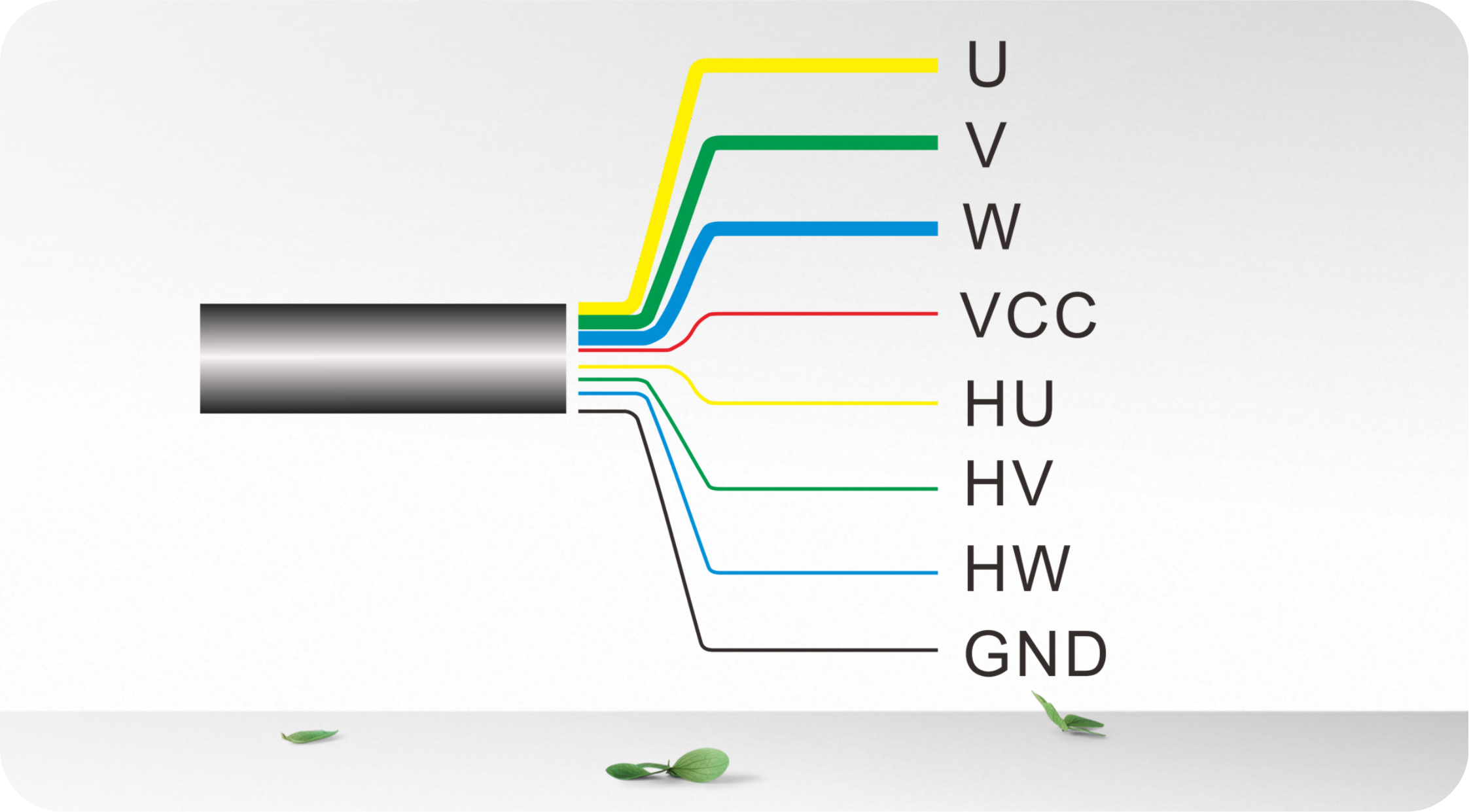

Motor Lead Wire Definition

Working Environment

Storage Environment

The movement should be stored in a dry and ventilated warehouse,

and the suitable temperature in the warehouse should be kept within the range of 5℃~35℃. The appropriate

temperature in the warehouse should be kept within the range of

5℃~35℃, the relative humidity should not be higher than 65, and

harmful gases, vapors and dust should be prevented from intruding.Operating Life

The movement has a working life of ≥5 million cycles within the

range of normal gate length and speed.Gate Pole Mounting Plate-Octagonal Pole

Barrier Commissioning Steps

Step 1: Match The Rod And Spring

Stop the gate lever at about 45 degrees and check whether the lever

will slowly drop or open the gate (if the gate is opened, explain the spring tension is too large (the rod is

allowed to open the brake slowly if the spring tension is slightly

larger). If the rod falls indicating insufficient spring tension).Step 2: Limit Of Self Inspection Learning Switch Of Track Gate

- The normal startup of the controller is "00:00" and "e-00"

alternately displayed. Press and hold the controller "close / turn up" for 2 seconds, and the track gate operates in the

direction of closing. The controller scrolls from left to right to

display "0 0 0 0", and the buzzer sounds rhythmically. When the

motor runs to the closing limit, the controller displays static "0

0 0 0" and the buzzer stops ringing. At this time, the closing

self-test is completed.

- After the closing self-test is completed, press and hold the

controller "open / down" for 2 seconds, and the track gate operates in the opening direction. The controller

scrolls from left to right to display "0 0 0 0", and the buzzer

sounds rhythmically. When the motor runs to the opening limit, the

controller buzzer sounds for a long time. At this time, the opening

self-test is completed, and the gate can operate normally.

Step 3: Adjust The Horizontal And Vertical Position Of The Gate

Lever- The pole exceeds 90 degrees after driving to the position (adjust

the P-9 parameter to a large scale); The pole is less than 90 degrees(reduce the P-9 parameter).

- Close to the position where the pole is higher than the horizontal

position (reduce the P-6 parameter); The pole is below the level position (increase P-6).

Note: 1. Judge whether the horizontal position of the fence pole

and the advertising gate is in place (the pole contacts the ground

motor will stop immediately (if the motor is still rotating after

it is in placeincrease the P-6 parameter until the motor does not

rotate after the pole reaches the ground.After debugging the parameters, the switch needs to be operated to

see the position change.Key Operation

The controller has four keys, namely "on / down", "return / stop",

"set / save" and "off / up". You can set various parameters of the main board through these four keys.Shortcut Key Operation

- Press the "on / down" button once in the mode without inserting the

motor cable to display the software version number; Press the "off / up" key once to display the

software date.

- In the normal working mode, under the display time page of the

digital tube, short press "set / save" once to display the current value, short press "set / save" for the second time to

display the change rate of hall, and short press "set / save" for

the third time to display the internal voltage value of the

controller; Short press "set / save" for the fourth time to display

the power supply voltage value;

Key Function Description

Set / save key: enter the setting state and save the setting value.

On / down key: press this key to open the gate in normal working

state. After entering the setting state, you can use this key to add menu items or adjust the setting value

upward. In the parameter setting state, short press to add one each

time. Press and hold continuously until the maximum value is

reached, and then add from the minimum value.

Off / up key: press this key to close the gate in normal working

state. After entering the setting state, you can use this key to reduce menu items or adjust the setting value

downward. In the parameter setting state, short press to subtract

one at a time. Long press to continuously decrease to the minimum

value and then decrease from the maximum value.

Return / stop key: in normal working state, press this key to stop

the brake. In the setting state, you can exit the setting state or return to the previous menu.

Parameter Menu

Operating Instructions

You can enter the parameter setting state by long pressing the "set

/ save" button for 3 seconds, and the LED will display "P-X". Select the menu items by pressing the two

buttons "on / down" and "off / up" for a short time or a long time.

Short press to increase or decrease one item at a time, and long

press to increase or decrease continuously. Press the "set / save"

key again to enter the setting of the specified item, and the

"return / stop" key to exit the setting. After setting the

specified parameters, you must press the "set / save" key to

confirm it. The parameters set by pressing the "return / stop" key

will not take effect. If there is no key within 45 seconds, the

buzzer on the control panel will sound for a long time, exit the

setting state and return to the normal working state.Parameter Command Value Table

- For all places involving angles, the closing position is 0 degrees.

- When the power supply voltage is too large (> 27V) or too small

(< 18V), the controller will automatically protect and give an alarm.when the controller is protected, the

motor, light box, ground sensor and other equipment will not work.

Remote Control Function

- Remote control pairing: long press the controller "set / save" for

three seconds, find the P-F item, and press the "set / save" again to display "000". At this time, press any

key of the remote control. At this time, after the controller makes

a long sound, the display changes to P-F, indicating that the

remote control is matched successfully.

- Clear the remote controller: long press "set / save" on the main

board for three seconds, find the P-F item, press "set / save" again to display "000", adjust the value to 253,

and press "set / save" again. At this time, after the main board

makes a long sound, the display changes to P-F, and all remote

controllers will be cleared.

- Fleet mode: long press "set / save" on the controller for three

seconds, find item p-8, and then press "set / save" to display "0", adjust the value to 4, and then press "set / save"

to exit the menu; After the road gate is opened in place, press the

stop button of the remote controller for more than 2 seconds, and

the fleet mode will start; To turn off the fleet mode, just press

the off key of the remote controller.

Parameter Transfer Steps

Step 1: debug a template

Step 2: connect the template with the new controller

Step 3: power on the new controller

Step 4: long press the " down" button of the template, and check

the "s -- s" displayed on the new controller, then the parameter transfer is successful

Common Problems And Solutions

Solution: check whether the left-right rotation mode of the P-D

motor matches the current motor or not (you can re power on the controller after changing the parameters and

conduct self-test again. Please refer to "Chapter 1, subsection 6,

step 2" for whether the self-test of the track gate is normal)Solution: adjust the controller menu P-9 or P-6 parameters (refer

to the parameter table for menu functions)Set the P-18 parameter of the controller to 1. If the relay is

opened or closed once, it indicates that it has been opened / closed in place

Pay attention to observe whether the motor stops when the gate

lever is in place, which means it is in place. If the gate lever is in place and the motor is still running, it is

necessary to change the P-6 or P-9 parameters.

In the process of switching on and off, the nixie tube will have a

dynamic "1" display. If the nixie tube display returns to the time interface, it indicates that it has been in

place.

Solution: A. check whether the P-C parameter turns on the

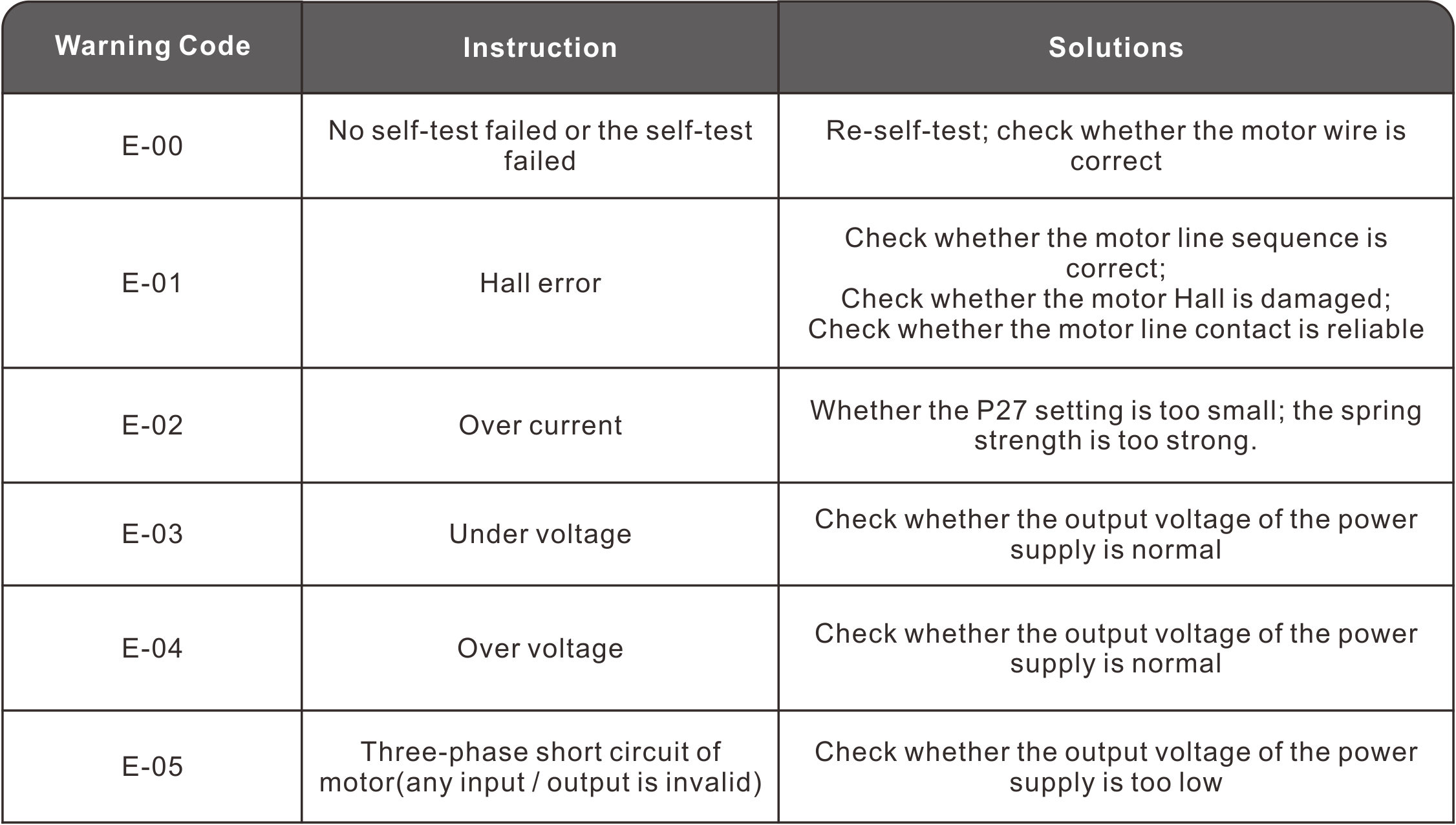

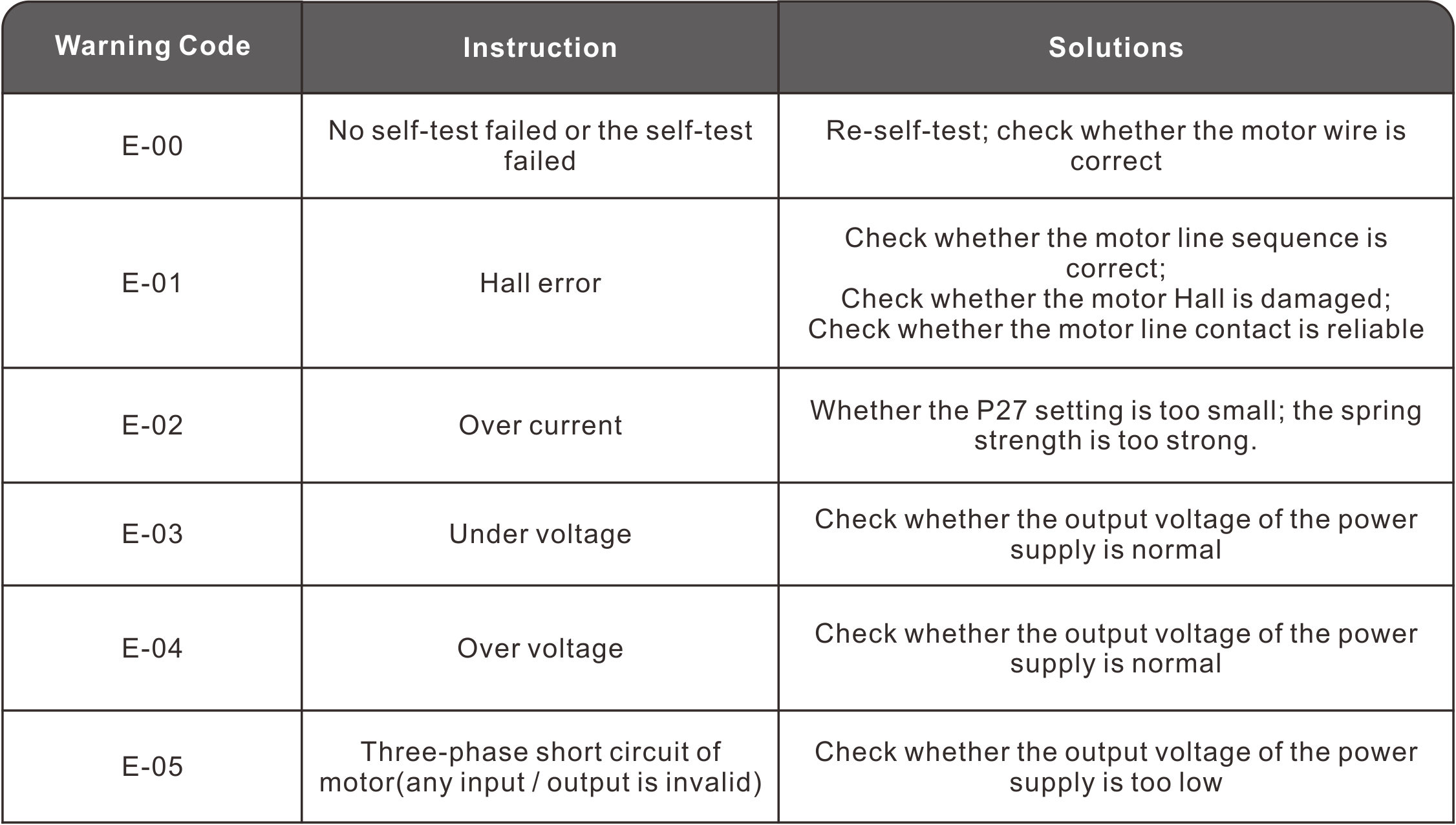

resistance rebound (if the controller parameter is greater than 100, the resistance rebound function fails)Solution: increase the value of P-C rebound function parameterSolution: increase the stability value of P-3 in placeError codes and Solutions

| BR-110 | BR-110F | BR-110BY | BR-110L | BR-110H |

Straight arm version Straight arm version

Lifting time: 3s 6s |  High speed version High speed version

Lifting time 1.5s |  LED ligtht version LED ligtht version

Lifting time: 3s 6s |  90° Folding arm version 90° Folding arm version

Lifting time: 3s 6s |

180° Folding arm version Lifting time: 3s 6s |

| BR-121 | BRDC-110 | BDC-1 | BRC-433R | BRC-443T |

Fence arm version Lifting time: 6s |

DC power economy version Lifting time: 1.2-5s |  |  |  |

Straight arm version

Straight arm version High speed version

High speed version LED ligtht version

LED ligtht version 90° Folding arm version

90° Folding arm version